All parts and equipment used in construction is new and warrantied by the manufacturer for a period of at least one year. Fabricated structures are warrantied free of defects in material and workmanship for a period of one year.

WE BUILD IT, WE BACK IT, THATS IT!

"STANDARD EQUIPMENT AND SPECIFICATIONS FOR ALL TOWBOATS

1) Vertical exhaust with perforated stainless guards.

2) Buck Algonquin bronze packing gland with gor-tex drip proof packing.

3) Perko navigation lights.

4) Devoe epoxy coatings, Including Inorganic zinc Undercoater.

5) Johnson weld on push knee pads.

6) Sand blasted inside and out.

7) A 36 prime domestic plate (certification available upon request).

8) 3/8” thick rounded hull corners

9) Full length engine stringers.

10) All seams, butts, and corners welded 100% inside and out. Intermittent welding of frames 4” on 4” off alternate sides.

11) All welding is continuous wire feed mig process usingA.B.S. approved wire and gas.

12) Full instrumentation includes tach, oil pressure, water temperture, and volts, Cummins factory panel.

13) Anti-fouling paint Devoe A.B.C. applied to underwater areas.

14) 1200 G.P.H. Rule electronic auto pump.

15) Steering full power hydraulic, with jog stick and rudder angle indicator.

16) 2 ½ “ Stainless steel Aquamet shaft."

17) 12 circuit distribution panel.

18) Pilot house and engine room lights.

19) 4 blade bronze propeller 30” x 24”

20) Pilot house front windows angled out. Opening center window.

21) One towing bit and four cleats.

22) Rudder linkages protected with framed in cover.

23)Access hatch and ladder to engine room.

24) New Cummins QSB-305, 305 H.P. Two year warranty. 3:1 Twin Disc.New power packages include factory

instrument panels and new transmissions with full factory warranties. Factory certified installation.

25) Six Point vibration isolation mounts.

26) Morse Control 33C cables

27) Doublers on all hull penetrations and deck fittings.

28) Increased capacity closed cooling system.

29) Coolant tanks with level indicators.

30) Two 5 ton Beebe/Wintech winches, with mounts and fairleads."

"STANDARD STRUCTURAL SPECIFICATIONS FOR ALL TOWBOATS

PLATING: ¼ “ A 36 Prime Domestic, hull and bullworks. ¼ “ on pilot house and deck house.

FRAMING: Longitudinal framing, 3/8” x 3” flat bar, Bulkheads, transom, headlog, deck, and sides. Maximum spacing 24”. Transverse framing, 3/8” x 6” flat bar, 72” maximum spacing.

BOTTOM: Transverse framing, ½ “ x 5” flat bar, 18” maximum spacing.

SHAFT AND RUDDER TUBES: Minimum 3/8” wall Domestic pipe. Propeller shaft fully inclosed.

RUDDERS AND PROPELLERS: Fully protected by full skeg capable of supporting full weight of the boat.

KEEL COOLERS: 8’ x 11.5 channel. Fairing plates front and rear. Welded 100% and pressure tested.

PUSH KNEES: Extend 4’ up from deck and 2’ below deck.

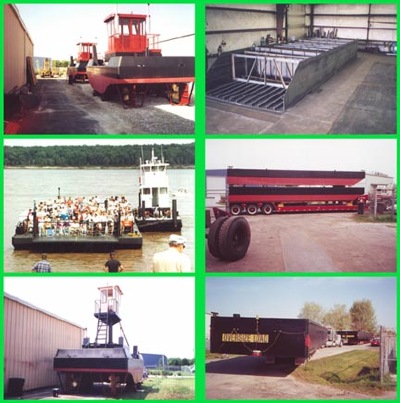

All structural specifications can be increased P.O.R. We will not decrease.All of our welding is done with the continuous wire feed (MIG) welding process, using the finest quality wire and gases. Close inspection of the welds shows the difference. If you compare our specifications with our competitors you will see our framing is heavier and closer. Our welding methods and schedules exceed all recognized classification society’s recommendations. Our boats are straighter, heavier, and stronger yet they are not more expensive. We do not do this by working cheap, we do it by working smart. Instead of building small boats and barges in a ship yard environment exposed to the weather and working on the ground, We build in a modern automated factory. The result is working with a smaller staff of highly skilled people, which allows us to closely control quality and production. We look at special requests as interesting challenges instead of unnecessary burdens.

These are only a few of the differences between us and them. If your considering a boat or barge we urge you to shop around. Before you decide come and see us and we think you’ll agree, that dollar for dollar and pound for pound we offer the most well

designed and highest quality product available."

"SUPER TRIUMPH

25’ x 14’ x 6’ Twin Screw Truckable Towboat

Approximately 42,000 lbs.

As seen in picture:

8’ x 8’ 7’ deck house with front access. 4’ x 7’ x 7’ pilot house with 16’ eye level.

Walk way around entire pilot house. Full bullworks around entire vessel, with freeing ports. 500 gallon independent fuel tank. Two 1400 CCA 8D batteries. Two steering

rudders. Two new Cummins QSB-305’s, 610 H.P. Two year warranty."

"VICTORY

25’ x 14’ x 5’ Twin Screw Truckable Towboat

Approximately 33,000 lbs.

As seen in picture:

Standard pilot house 4’ x 7’ x 7’ on a 3’ trunk with an 11’ eye level. Also available with a pedestal to provide 16’ eye level. 4’ x 4’ x 7’ pilot house on pedestal. Pilot house base is 4’ x 6’. Bull rail around bow, stern, and 6’ up the sides from the bow and stern. 1400 CCA 8D battery. 350 gallon independent fuel tank. Two steering rudders.

Two new Cummins QSB-305’s, 610 H.P. Two year warranty."

"CONQUEST

25’ x 12’ x 5’ Single Screw Truckable Towboat

Approximately 25,000 lbs.

As seen in picture:

Standard pilot house 4’ x 7’ x 7’ on a 3’ trunk with an 11’ eye level. Also available with a pedestal to provide 16’ eye level. 4’ x 4’ x 7’ pilot house on pedestal. Pilot house base is 4’ x 6’. Bull rail around bow, stern, and 6’ up the sides from the bow and stern. 1400 CCA 8D battery. 250 gallon independent fuel tank. One steering rudder,

and two flanking rudders. New Cummins QSB-305’s, 305 H.P. Two year warranty."

"ENDEAVOR

25’ x 10’ x 4’ Single Screw Truckable Towboat

Approximately 21,000 lbs.

As Seen in picture

Standard pilot house 4’ x 4’ x 7’ on a 2’ trunk with an 11’ eye level. Bull works around stern and 6’ up the sides from the stern. 1400 CCA battery. 200 gallon independent fuel tank. One steering rudder, and two flanking rudders. New Cummins

QSB-305’s, 305 H.P. Two year warranty."

“GOLIATH”

NEW TOWBOAT UNDER CONSTRUCTION

GENERAL:

HULL DIMENSIONS: 50’0” Long X 15’0” Wide X 7’0” Molded Depth X 5’ Draft.

DECK HOUSE: 20’ Long X 9’ Wide X 7’ High, Eight windows and two doors.

PILOT HOUSE: 10’ Long X 8’ Wide X 7’ High, Fourteen windows and one door.

PUSH KNEES: 2’ Wide extending 6’ above deck and 3’ below, faced with Jonson rubber weld on push knee pads.

BULLWORKS: Extending 19” above main deck formed with 4” cap and lip. Heavily framed and angled in with rounded corners and freeing ports around entire vessel.

STERN: Steering and flanking rudder linkages and hydraulic cylinders are below main deck and fully protected. Lubrication and hydraulic maintenance VIA Lazerate.

HATCHES: One 18” x 24” raised rectangular hatch provides entry into the aft void space. Normal engine room entry from main deck at rear of deckhouse VIA weather tight door and stairway. Main engine replacement by removal of deckhouse VIA bolted sill. Access to pilot house from rear stairway. Access to pilot house roof and electronics mast from rear ladder.

ENGINE ROOM: 20’ Long X 15’ Wide X 7’ High well lit and ventilated with steel flooring.

FUEL: 1300 Gallons in two independent tanks with internal baffles.

STRUCTURALS:

HULL: ¼ “ A36 Prime Domestic plate throughout.

FRAMING: Sides 3/8” X 4” flat bar 15” maximum spacing (Longitudinal).

3/8 “ X 6” flat bar maximum 72” spacing (Transverse).

DECK: 3/8” x 4” and 3/8” x 6” flat bar 12” maximum spacing (transverse).

BOTTOM: ¾ “ X 5” flat bar maximum 18” spacing (Transverse). 3/4” x 8” flat bar in way of engine stringers.

BULKHEADS: 3 watertight - ¼ “ plate with 3/8 “ X 4” framing 20” maximum spacing.

SUPERSTRUCTURES: ¼ “ Plate throughout, heavily framed throughout.

SKEGS: Full length skegs constructed of 1” X 4” flat in T configuration supported by multiple V struts designed to withstand repeated grounding and support full weight of vessel.

RUDDERS: 2 Steering 4 flanking. ¼ “ plate with 3/8” X 3” flat bar stiffeners both sides large V brace under steering rudders.

NOTE: Entire underwater running gear is overbuilt and designed for shallow water high abuse service.

MACHINERY:

MAIN ENGINES: Two new John Deere 6081 Turbo 375 H.P. @ 2400 RPM. Electronic controlled engine with full instrumentation and fully programmable for varying operation parameters. Installation approved by John Deere with two year factory warranty. (Extended warranty available)

TRANSMISSION: 2 Tonan 729 5:1 ratio (New).

SHAFTS: Two 3” Stainless steel Aquamet 22.

PROPELLERS: Two 46” X 37” Ellis 4 blade style I workboat counter rotating.

ENGINE MOUNTS: Bushings Inc. adjustable vibration mounts.

EXHAUST: Dry through vertical stacks with vibration flex sections.

COOLING SYSTEMS: All machinery is keel cooled with integral coolers of 8” X 11.5 channel welded to bottom of vessel with large engine mounted expansion tanks.

CONTROLS: Morse single lever MT3 with 33 C cables.

INSTRUMENTATION: Complete monitoring all systems V.D.O. and gauges. Audio visual alarm for high temperature and low oil. (John Deere factory panels)

ENGINE ELECTRICAL: 3 Group 8 D starting batteries. Two 80 amp alternator. Enclosed harness with pilot house start and stop.

GENERATOR: One 21 K.W. 1800 RPM Kubota-Newage 4 cylinder diesel, providing 120V and 240V service, with unit mounted main distribution panel and shore power transfer switch. Safety shut downs, on engine start and stop, and on engine oil, temperature, volt, and hour gauges. Keel cooled. Vibration isolation mounts. 3 Year factory warranty on engine, one year on entire unit.

STEERING: Full power hydraulic system with direct coupled Vickers pumps. One per engine. Flanking rudders are jog stick controlled with rudder angle indicator. Fully adjustable from 3 seconds H.O. to H.O. to infinitely slow. Steering rudders are the same and in addition have wheel control 5 turns from H.O. to H.O. There is no change over required to steer by jog or wheel whichever one you grab is the one that is live. Steering cylinders are Vickers 3” bore X 20” stroke with 1 3/8” rod.

LIGHTING: Full navigation and towing lights, pilot house, engine room and deckhouse have fluorescent lighting.

COATINGS: HULL: Exterior, Devoe Catha Cote 302 H followed by Devoe 201 K followed by Devoe Devtar 5A 221 black and Devoe ABC 3 red antifouling.

Interior engine room, Devoe Bars Rust # 235 beige. Aft steering compartment and void spaces coated with Eureka fluid film rust preventative.

SUPERSTRUCTURES: Interior and Exterior Devoe 201 K followed by Devoe 389 two part Urethane oxide, choice of color.

NOTE: All coatings are 2 part epoxies applied to manufactures recommendations.

CATHODIC PROTECTION: Ten 12lb. weld on zinc's on underwater areas.

MISCELLANEOUS: Improved hull design gives this vessel excellent handling characteristics with a free running speed of 10 knots and an estimated bollard pull of 15,000 lbs.

Its smooth, quiet and easy to operate.

Here at Progressive Industrial we have a long standing reputation for building truckable towboats that are a cut above the rest. I believe our 50’ boats are the best example of this and represent the best value of all the boats we offer. At 15’ wide they are easily truckable. They are smooth, quiet, easy to maneuver and very powerful for there class. The interior can be easily finished off to provide overnight accommodations and best of all its a new boat at a used boat price.

The pride in workmanship and quality materials that went into this vessel will be self evident on inspection.